|

管理员

|

这个 3D打印的磁性结构体能够爬行、滚动、跳跃,甚至还能玩接球

Magnetic 3-D-printed structures crawl, roll, jump, and play catch New printing technique could be used to develop remotely controlled biomedical devices. 美国麻省理工学院的工程师们创造了一种 3D 打印的软性结构体,其运动能通过外部磁场控制,就好似没有绳子的木偶一般。 这一结构体能够在磁铁的控制下进行多种变形:一个在磁力作用下,光滑的表面起了波纹的环;一个一端能张合的管道;一个能自行折叠的金属片;一个蜘蛛形的“爪钩”,能够爬行、滚动、跳跃,还能及时抓住一闪而过的球。它甚至还能在磁铁的引导下用自身包裹住一粒小药片,将药片运送到桌子的另一端。

这些磁力结构体的背后是一种加入了微小磁性颗粒的 3D 打印墨水。研究人员在 3D 打印机的喷嘴周围安装了一个电磁铁。当墨水通过喷嘴时,电磁铁导致其中的磁性颗粒朝同一方向排布。通过控制 3D 打印结构体各个部分的磁场方向,研究人员制作出的结构和装置可以在几乎瞬间之内变化成复杂的形状。除此之外,由于结构体的各个部分都会对外部磁场作出响应,它们也可以移动。 麻省理工学院机械工程和土木与环境工程学院的赵选贺教授表示,这一磁性结构体所使用的相关技术能够被用来制造磁控的生物医学设备。 “我们认为这项技术在生物医学领域有非常大的前景。”赵教授说,“举个例子来说,我们可以在某根血管周围放置一个结构来控制血液的流动,或者使用磁铁来引导另一个装置通过胃肠道,从而采集图像,提取组织样本,清除阻塞或将某些药物输送到特定位置。在设计和模拟后,我们可以直接将所需要的磁性结构打印出来。”

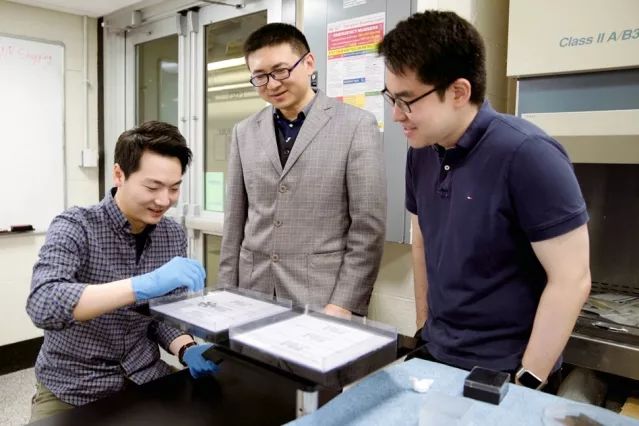

图丨Yoonho Kim, 赵选贺, Hyunwoo Yuk(从左至右) 赵教授和他的同事们在 6 月 13 日的《自然》杂志中发表了这一成果。论文中的合著者有麻省理工学院的 Yoonho Kim、Hyunwoo Yuk、Ruike Zhao,还有新泽西理工学院(New Jersey Institute of Technology)的 Shawn Chester。 日新月异的领域

该团队开发的磁性结构体属于“软驱动装置”——在机械手段下能进行形状变换或移动的柔软、可变形材料,例如随着温度或 pH 变化而膨胀的水凝胶装置; 在充足的刺激(如热量或光照)下变形的形状记忆聚合物和液晶弹性体; 通过空气或水驱动的气动和液压装置; 或是在电压下拉伸的电介质弹性体。 但是水凝胶、形状记忆聚合物和液晶弹性体的变形过程都非常缓慢;气动和液压装置都必须将相关设备和气泵、水泵连接起来,因此它们效率不高、难以远程控制;电解质弹性体的变形需要非常高的电压——通常要超过一千伏。 “目前没有一个理想的软性机器人可以在人体或类似的封闭的空间内不受限制地执行任务。”研究人员 Kim 说,“这就是为什么我们认为磁控装置这一理念有很大的发展空间。磁控装置快速、有力、对身体伤害较小,并且可以远程控制。”

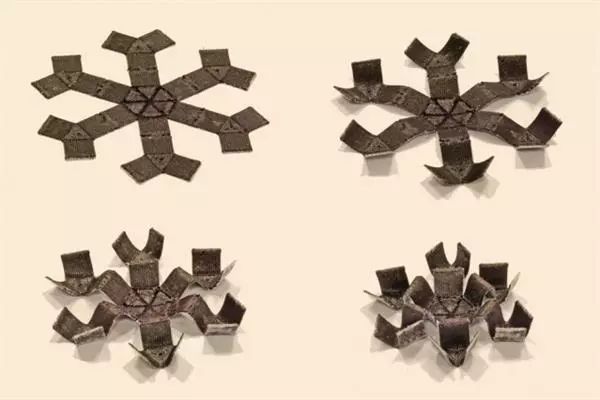

图丨3D打印结构 除了麻省理工这一团队之外,已有其它研究人员制造出了磁力驱动的材料,不过他们制造的装置只能完成一些相对简单的动作。大多数情况下,研究人员将聚合物溶液与磁珠混合,然后将混合物倒入模具中。一旦混合物固化,研究人员会在将结构从模具中取出之前对其施加磁场,从而使磁珠均匀磁化。 “在我们之前,研究人员只做出了能够延长、缩短和弯曲的结构体。”Yuk 说,“我们的挑战在于:该怎样做出一个能执行更复杂任务的结构体或机器人呢?” “区域”游戏

麻省理工的研究团队没有制造内部磁场方向完全一致的结构体;他们在结构体中创建了磁性“区域”——结构体中的独立部分,其中的磁性粒子拥有与其它区域不同的磁场方向。当结构体暴露于外部磁场中的时候,由于各部分粒子对外部磁场的响应不同,每个部分的移动方式都不尽相同。正因为如此,该小组认为他们的结构体能够执行更复杂的细致动作。 通过他们的 3D 打印平台,研究者们能够打印出一个结构体的不同部分,也就是不同的磁性“区域”。在打印每个“区域”时,他们都会改变打印机喷嘴周围电磁铁的方向,从而调整特定“区域”中磁性颗粒的方向。 该团队还开发了一种物理模型,用于预测印刷结构在磁场下如何变形。这一模型的变量包括印刷材料的弹性、结构体中各个“区域”的形状,以及施加外部磁场的方式。该模型可以预测整个结构体变形或移动的方式。Ruike 发现模型的预测结果与团队用不同结构体进行实验的结果非常接近。

图丨3D打印结构 除了会起波纹的环、会开闭的管道,和类似蜘蛛的“爪钩”,研究人员们也制作了一些复杂的结构,例如一个能快速收缩或沿两个方向伸展的“拉胀”结构。赵教授和它的同事们也打印了一个印有嵌入电路和红绿 LED 灯的环。根据外部磁场的方向,环可以通过变形,点亮红灯或绿灯。 “我们已经开发了一个供其他人使用的打印平台和预测模型。人们可以设计自己的结构和“区域”形态,用我们的模型验证它们,并打印它们以实践各种功能。”赵教授说,“通过编译结构、“区域”和磁场等的复杂信息,我们甚至可以打印机器人等智能机器。” 佐治亚理工机械工程系的教授 Jerry Qi 表示,这一团队的成果将会引领一系列快速、远程控制软性机器人的设计与研发,尤其是在生物医学领域。 “他们的研究非常新颖。”Qi 教授并没有参与这项研究,但是对他们的工作给予了很高的评价。“人们可以在人体内使用软性机器人,或者在不易接触到的地方使用软性机器人。利用这篇论文讲述的这项技术,我们可以在人体外部施加磁场,无需在人体内使用任何布线。由于它们响应速度快,软性机器人可以在短时间内完成许多动作。这些都对于实际应用非常重要。” Magnetic 3-D-printed structures crawl, roll, jump, and play catch New printing technique could be used to develop remotely controlled biomedical devices. MIT engineers have created soft, 3-D-printed structures whose movements can be controlled with a wave of a magnet, much like marionettes without the strings. The menagerie of structures that can be magnetically manipulated includes a smooth ring that wrinkles up, a long tube that squeezes shut, a sheet that folds itself, and a spider-like “grabber” that can crawl, roll, jump, and snap together fast enough to catch a passing ball. It can even be directed to wrap itself around a small pill and carry it across a table. The researchers fabricated each structure from a new type of 3-D-printable ink that they infused with tiny magnetic particles. They fitted an electromagnet around the nozzle of a 3-D printer, which caused the magnetic particles to swing into a single orientation as the ink was fed through the nozzle. By controlling the magnetic orientation of individual sections in the structure, the researchers can produce structures and devices that can almost instantaneously shift into intricate formations, and even move about, as the various sections respond to an external magnetic field. Xuanhe Zhao, the Noyce Career Development Professor in MIT’s Department of Mechanical Engineering and Department of Civil and Environmental Engineering, says the group’s technique may be used to fabricate magnetically controlled biomedical devices. “We think in biomedicine this technique will find promising applications,” Zhao says. “For example, we could put a structure around a blood vessel to control the pumping of blood, or use a magnet to guide a device through the GI tract to take images, extract tissue samples, clear a blockage, or deliver certain drugs to a specific location. You can design, simulate, and then just print to achieve various functions.” Zhao and his colleagues have published their results today in the journal Nature. His co-authors include Yoonho Kim, Hyunwoo Yuk, and Ruike Zhao of MIT, and Shawn Chester of the New Jersey Institute of Technology. A shifting field The team’s magnetically activated structures fall under the general category of soft actuated devices — squishy, moldable materials that are designed to shape-shift or move about through a variety of mechanical means. For instance, hydrogel devices swell when temperature or pH changes; shape-memory polymers and liquid crystal elastomers deform with sufficient stimuli such as heat or light; pneumatic and hydraulic devices can be actuated by air or water pumped into them; and dielectric elastomers stretch under electric voltages. But hydrogels, shape-memory polymers, and liquid crystal elastomers are slow to respond, and change shape over the course of minutes to hours. Air- and water-driven devices require tubes that connect them to pumps, making them inefficient for remotely controlled applications. Dielectric elastomers require high voltages, usually above a thousand volts. “There is no ideal candidate for a soft robot that can perform in an enclosed space like a human body, where you’d want to carry out certain tasks untethered,” Kim says. “That’s why we think there’s great promise in this idea of magnetic actuation, because it is fast, forceful, body-benign, and can be remotely controlled.” Other groups have fabricated magnetically activated materials, though the movements they have achieved have been relatively simple. For the most part, researchers mix a polymer solution with magnetic beads, and pour the mixture into a mold. Once the material cures, they apply a magnetic field to uniformly magnetize the beads, before removing the structure from the mold. “People have only made structures that elongate, shrink, or bend,” Yuk says. “The challenge is, how do you design a structure or robot that can perform much more complicated tasks?” Domain game Instead of making structures with magnetic particles of the same, uniform orientation, the team looked for ways to create magnetic “domains” — individual sections of a structure, each with a distinct orientation of magnetic particles. When exposed to an external magnetic field, each section should move in a distinct way, depending on the direction its particles move in response to the magnetic field. In this way, the group surmised that structures should carry out more complex articulations and movements. With their new 3-D-printing platform, the researchers can print sections, or domains, of a structure, and tune the orientation of magnetic particles in a particular domain by changing the direction of the electromagnet encircling the printer’s nozzle, as the domain is printed. The team also developed a physical model that predicts how a printed structure will deform under a magnetic field. Given the elasticity of the printed material, the pattern of domains in a structure, and the way in which an external magnetic field is applied, the model can predict the way an overall structure will deform or move. Ruike found that the model’s predictions closely matched with experiments the team carried out with a number of different printed structures. In addition to a rippling ring, a self-squeezing tube, and a spider-like grabber, the team printed other complex structures, such as a set of “auxetic” structures that rapidly shrink or expand along two directions. Zhao and his colleagues also printed a ring embedded with electrical circuits and red and green LED lights. Depending on the orientation of an external magnetic field, the ring deforms to light up either red or green, in a programmed manner. “We have developed a printing platform and a predictive model for others to use. People can design their own structures and domain patterns, validate them with the model, and print them to actuate various functions,” Zhao says. “By programming complex information of structure, domain, and magnetic field, one can even print intelligent machines such as robots.” Jerry Qi, professor of mechanical engineering at Georgia Tech, says the group’s design can enable a range of fast, remotely controlled soft robotics, particularly in the biomedical field. “This work is very novel,” says Qi, who was not involved in the research. “One could use a soft robot inside a human body or somewhere that is not easily accessible. With this technology reported in this paper, one can apply a magnetic field outside the human body, without using any wiring. Because of its fast responsive speed, the soft robot can fulfill many actions in a short time. These are important for practical applications.” This research was supported, in part, by the National Science Foundation, the Office of Naval Research, and the MIT Institute for Soldier Nanotechnologies. -End- 编译:石筱玉 校审:XHR 参考链接:June 13, 2018 Jennifer Chu | MIT News Office http://news.mit.edu/2018/magnetic-3-d-printed-structures-crawl-roll-jump-play-catch-0613 2018-06-18 10:59 机器人/中国移动/设计

这个 3D 打印的磁性结构体能够爬行、滚动、跳跃,甚至还能玩接球 http://www.sohu.com/a/236372127_354973 |

一键同布到我集网·各家微博

一键同布到我集网·各家微博